Difference between revisions of "Virtual designs into physical objects"

m (Methods for turning collaborative designs into real objects moved to Turning collaborative designs into physical objects) |

|||

| (22 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

<div style="float:right; width:100%;"> | <div style="float:right; width:100%;"> | ||

{{frame1|Intro}} | {{frame1|Intro}} | ||

| − | |||

</div> | </div> | ||

<!-- ******* START OF LEFT COLUMN ******* --> | <!-- ******* START OF LEFT COLUMN ******* --> | ||

<div style="float:left; width:50%;"> <!-- This width add to the the margin below to equal 100%--> | <div style="float:left; width:50%;"> <!-- This width add to the the margin below to equal 100%--> | ||

| − | {{frame1| | + | {{frame1|Sections}} |

{{frame1|Mail order machining}} | {{frame1|Mail order machining}} | ||

| − | {{frame1| | + | {{frame1|Contract manufacturing facilities}} |

| + | {{frame1|More advanced manufacturing concepts}} | ||

| + | '''Keywords:''' | ||

| + | :Digital manufacturing, open manufacturing, open-source manufacturing, digitla fabricator, fabbing | ||

</div> | </div> | ||

<!-- ******* START OF RIGHT COLUMN ******* --> | <!-- ******* START OF RIGHT COLUMN ******* --> | ||

<div style="float:right; width:49%"> <!-- This margin should be right of the above --> | <div style="float:right; width:49%"> <!-- This margin should be right of the above --> | ||

| − | {{frame1|Rapid prototyping machines}} | + | {{frame1|Get your hands dirty}} |

| − | {{frame1| | + | {{frame more1|Rapid prototyping machines}} |

| − | {{frame1| | + | {{frame1|Fab Labs}} |

| + | {{frame1|See also}} | ||

| + | <big>"The future is already here - it is just unevenly distributed"</big> | ||

| + | <div style="text-align: right;">- William Gibson</div> | ||

</div> | </div> | ||

{{portalpageend}} | {{portalpageend}} | ||

| + | |||

| + | {{detailed tour|Open collaborative design|Free and open-source computer-aided design}} | ||

Latest revision as of 13:24, 16 December 2012

|

At some point virtual designs such as Computer-aided design (CAD) models, need to be turned into physical objects, which unfortunately isn't as straightforward as downloading software from a website. Building, testing and modifying physical designs requires effort, time and material cost, although with access to emerging flexible computer-controlled manufacturing (digital fabrication) this complexity and effort becomes drastically reduced and highly repeatable.

Some of the ways that collaborative designs created on a computer can be physically forged range from getting your hands dirty and crafting it yourself, to sending the design, or at least parts of it, as an electronic file to an increasing number of computer-controlled manufacturing systems such as rapid prototyping or advanced multi-axis CNC machines What is illustrated in this section is that the world of atoms is starting to catch up with the world of bits in terms of ease of control and duplication. We are entering the age of digital manufacturing. Objects and machines are boiled down to pure information which can be instantly transmitted around the world and recreated physically wherever these 'fabbers' exist. Here are some of the increasing number of methods available to bring virtual designs to life...

A company called eMachineShop takes custom fabrication a step further in terms of ease of use. The US-based company supplies a fairly simple computer-aided design program that once materials have been assigned to the geometric forms an automatic bill of materials can then be calculated. When the user is happy with the design and the price, the information is sent over the internet to eMachineShop where the parts are fabricated using the appropriate computer-controlled machinery. The finished parts are then mailed back to the user.

eMachineShop have cleverly incorporated the limitations of their physical fabrication processes into the CAD program. This means that the company can be sure that they can make anything designed using their software. The company claims to handle part quantities from one-offs to runs up to a million. A related company is Pad2Pad that provides a similar service for the creation of printed circuit boards (PCB). They also provide free design software that has circuit error-checking and costing built-in. When the design is completed it is sent electronically to the company who then fabricate the PCBs and return by post. They do not currently populate the boards with electronic components, although it is likely to be only a matter of time before a full electronics service such as this is offered. There is on-going research to create functional circuitry via cheaper methods, such as inkjet printing [1], that will make creating electronic circuits even more accessible. See also http://www.batchpcb.com A group of people all wanting the same item to be made could get together and send the details of the design to a large-scale contract manufacturing and assembly company to make use of specialist facilities and economies of scale. This might be a 'base item' and each individual then customises and finishes off the product according to their tastes. The item could be anything from a car, a mobile phone, a computer or an entirely new machine or device that has only recently been thought up... See also Wired article "In the Next industrial revolution, atoms are the new bits". See also Joy de vivre concept. At some stage open-source systems will likely compete with this type of manufacturing too, bypassing the commercial aspect - however it makes some interesting large-scale things possible right now.

For more information on this see the section on advanced automation and automated infrastructure.

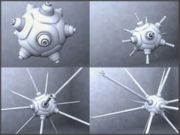

Keywords:

Craft the item yourself or in a group according to plans using your own skills and tools plus readily available 'off-the-shelf' components. Lo-tech but effective. Step-by-step 'how-to' guides, sometimes with video, are increasingly being published on the internet for this kind of project. See Instructables as a good example. Or someones else's... Small-scale local engineering firms that will make custom items to order have always been around, often specialising certain materials and techniques. Rapid prototyping machines, sometimes called 3D printers, are now commonly used in the design and manufacturing industries for creating solid three dimensional objects straight from CAD models. Currently there are various limitations with these machines but in the near future the price will reduce rapidly, the number of different materials that can be used to make parts will multiply, the resolution will become steadily finer and the build-speed will increase. It is likely that these machines will soon be within the reach of ordinary people following a similar evolutionary path to computer printers. Mail order rapid prototyping services are already available.

Fab Labs (fabrication laboratories, or fabulous laboratories) are small scale workshops with modern computer controlled equipment such as...

...giving the ability within one room to create just about anything from engines to electronic devices. The concept was developed at the Center for Bits and Atoms at MIT. Around 34 fab labs have been set up around the world so far to give ordinary people in deprived areas access to this type of machinery to help people create machines and devices for themselves and their community. Commercial versions are now starting to spring too, see http://www.techshop.ws. Links

RepLabRepLabs: Open-source, replicable FabLabs. Very nascent but holds great promise as a concept. Conventional FabLabs use expensive commercial equipment - RepLab wants to reduce the cost by an order of magnitude and at the same time significantly increase functionality. RepLab is to be made entirely of machines whose designs are free and open-source, allowing anyone to build one, thus putting manufacturing of advanced electronics and machinery within anyone's reach. It would follow the RepRap principle of self-replication so that the equipment in a RepLab would be able to create another RepLab, just by downloading the designs from the Internet and inputting them to the machines. In principle: a multi-process, multi-material RepRap.

Articles"The future is already here - it is just unevenly distributed" - William Gibson

|

[print version]

[print version]  [update]

[update]  [site map]

[site map]Detailed tour:  previous page | next page

previous page | next page