Difference between revisions of "Additive manufacturing"

| Line 14: | Line 14: | ||

#Inevitability of 3D printers on home desktops (whether commercial or open-source) | #Inevitability of 3D printers on home desktops (whether commercial or open-source) | ||

| − | ==[[RepRap]]== | + | ==[[RepRap]] the self-replicating rapid prototyper== |

{{:RepRap}} | {{:RepRap}} | ||

==[[Fab@Home]]== | ==[[Fab@Home]]== | ||

{{:Fab@Home}} | {{:Fab@Home}} | ||

Revision as of 03:33, 23 February 2007

Main Page > Open collaborative design > Virtual designs into physical objects > Additive manufacturing

Main Page > Open collaborative design > Virtual designs into physical objects > Additive manufacturing

Rapid prototyping machines are like three dimensional printers that turn virtual designs on a computer into solid objects, by building up extremely thin cross-sectional layers, usually some kind of polymer, one on top of the other. Currently they are used mostly in industry to create accurate parts for developmental designs and prototypes. But they are increasingly being used in short manufacturing runs and is known in this circumstance as rapid manufacturing. These techniques are sometimes known as solid freeform fabrication.

There are various types: <unfinished>

- Intro

- Different types

- Materials

- Advantages

- Limitations

- Rapid manufacturing

- Inevitability of 3D printers on home desktops (whether commercial or open-source)

Contents

RepRap the self-replicating rapid prototyper

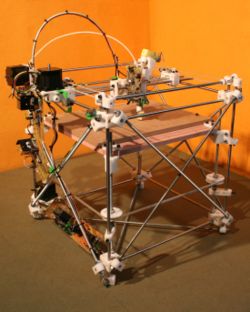

RepRap is rather special rapid prototyping machine. The name is short for self-replicating rapid prototyper and the project was started at the University of Bath by Dr. Adrian Bowyer, a Senior Lecturer in mechanical engineering.

The idea is to create a rapid prototyping machine that, as well as being able to construct useful three dimensional objects to order, is also able to create most of the parts necessary to build another rapid prototyping machine. So for a very low cost, someone with a RepRap should be able to clone a new machine to give to someone else.

It uses the Fused Deposition Modelling  (FDM) system of additive construction where a thermoplastic material is extruded very thinly from a computer controlled nozzle to slowly build up a three dimensional shape layer by layer.

(FDM) system of additive construction where a thermoplastic material is extruded very thinly from a computer controlled nozzle to slowly build up a three dimensional shape layer by layer.

However there are various of its own component parts that it cannot currently reproduce such as the stepper motor, microcontroller, extrusion nozzle and lubricant. However over time as the design evolves and becomes more sophisticated it is envisioned that there will be fewer and fewer parts that cannot be made by the machine itself.

Materials

The RepRap team intend to include nozzles for applying different materials during the build process:

- A thermoplastic - generally used to create structure of the object being made.

- Wood's

or Field's metal

or Field's metal  which are low melting point metal alloys used to create electrical circuits within three dimensions in the artefact being built

which are low melting point metal alloys used to create electrical circuits within three dimensions in the artefact being built - Ceramic slurry for hard and strong cement-like structures

- Silicone polymer used for gaskets, seals and flexible parts

- Plaster/cellulose mixes, PVA or icing sugar for temporary support material to allow overhangs to exist as the object is being built up. After the object is created these supports can be dissolved away using warm water

Open design

This is an open collaborative design project in that everything relating to it – the schematics, 3D CAD models of the components and the software to run it – are being released under the GPL license  which enables anyone to use, customize and evolve it. The terms of the GPL also mean that any improvements will likewise be available under the same license for others to benefit from.

which enables anyone to use, customize and evolve it. The terms of the GPL also mean that any improvements will likewise be available under the same license for others to benefit from.

External links

- Video introduction to RepRap v.2 ('Mendel')

- RepRap project website

- RepRap article on Wikipedia

- RepRep Research Foundation

- Dr. Adrian Bowyer explaining the concept of RepRap (PopTech video)

- 'Replication revolutionary', article from New Electronics, 29 December 2006 (pdf)

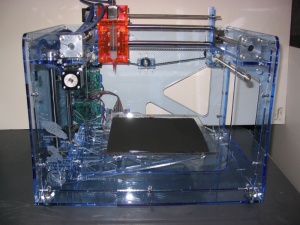

Fab@Home

Fab@Home is an open-source rapid prototyping machine with a syringe-based extrusion system from Cornell University.

- http://www.fabathome.org

- IEEE Spectrum article by Hod Lipson - covers many aspects of where this technology might be going

- Guardian article