Difference between revisions of "Additive manufacturing"

(→RepRap) |

|||

| Line 17: | Line 17: | ||

[[Image:RepRap 0.1 prototype.jpg|thumb|RepRap 0.1 prototype (created by Vik Olliver)]] | [[Image:RepRap 0.1 prototype.jpg|thumb|RepRap 0.1 prototype (created by Vik Olliver)]] | ||

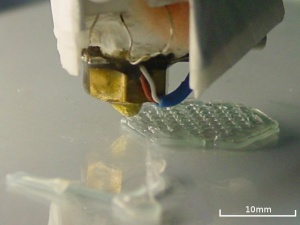

[[Image:Extrusion of hexagon 2nd layer closeup.jpg|thumb|RepRap 0.1 building an object]] | [[Image:Extrusion of hexagon 2nd layer closeup.jpg|thumb|RepRap 0.1 building an object]] | ||

| − | RepRap is rather special. The name is short for '''rep'''licating '''rap'''id prototyper. It is a project started at the University of Bath, UK by Dr. Adrian Bowyer,a Senior Lecturer in mechanical engineering. | + | RepRap is rather special. The name is short for '''rep'''licating '''rap'''id prototyper. It is a project started at the University of Bath, UK by Dr. Adrian Bowyer, a Senior Lecturer in mechanical engineering. |

| − | The idea is to create | + | The idea is to create a rapid prototyping machine that, as well as being able to construct useful three dimmensional objects to order, is also able to create all the parts necessary to build another rapid prototyping machine. So for a very low cost, someone with a RepRap should be able to clone a new machine for someone else. |

| + | |||

| + | This is an [[Open design]] project in that everything relating to the project - i.e. the plans, 3D models of the components and the software to run it are being released under the GPL license which enables anyone to make use of, customize and evolve them. But also means that any improvements should likewise be available under the GPL for other to benefit from. | ||

| + | |||

| + | Exceptions | ||

| + | |||

| + | When I last saw Adrian he said he was planning on incorporating four extruder nozzles, each applying a different material. | ||

http://en.wikipedia.org/wiki/RepRap_Project | http://en.wikipedia.org/wiki/RepRap_Project | ||

{{pagebgend}} | {{pagebgend}} | ||

Revision as of 23:25, 20 September 2006

|