| << Page in early stages >>

|

Main Page > Open collaborative design > Virtual designs into physical objects > Additive manufacturing Main Page > Open collaborative design > Virtual designs into physical objects > Additive manufacturing

Rapid prototyping and additive manufacturing machines are like three dimensional printers that can turn virtual designs on a computer into solid objects, by building up extremely thin cross-sectional layers, using polymers and more recently metals, built one at a time on top of each other. This is known generically as additive fabrication or additive manufacturing in contrast to CNC milling which is a subtractive process, starting from a larger solid block of material.

Currently they are used mostly in industry to create accurate parts for developmental designs and prototypes. But they are increasingly being used in short manufacturing runs and is known in this circumstance as rapid manufacturing.

There are a variety of types currently in use:

- Fused deposition modelling (FDM) which extrudes thin strands of molten material such as ABS

- Selective laser sintering (SLS) which fuses nylon powder or metals with a laser

- Electron-beam melting (EBM) which fuses metal powder using an electron beam in a vacuum

- Stereolithography apparatus (SLA) which cures liquid resin in a tank with an ultra-violet laser. Parts are brittle but can be fully transparent and has a very high resolution

- 3D printing which squirts out a UV curable resin from a matrix of nozzles. Recent machines can have variable colours and variable shore hardnesses, able to create a part that is has gradient of hardness along its length

- Powder and glue plus inkjet colour printing on the surface

- Paper cutting and lamination

<unfinished>

- Intro

- Different types

- Materials

- Advantages

- Current limitations

- Rapid manufacturing

- Inevitability of 3D printers on home desktops (whether commercial or open-source)

There will likely be a convergence of multi-tool rapid-prototyping machines and the shrinking of multi-machine fablabs, allowing sopisticated digital manufacturing from a single desktop device.

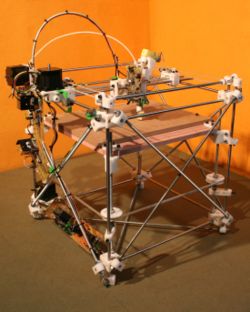

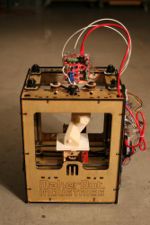

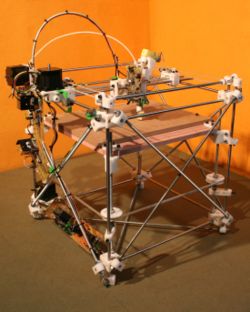

RepRap version 1.0 'Darwin'  Parts printed from a RepRap RepRap is rather special rapid prototyping machine. The name is short for self-replicating rapid prototyper and the project was started at the University of Bath by Dr. Adrian Bowyer, a Senior Lecturer in mechanical engineering.

The idea is to create a rapid prototyping machine that, as well as being able to construct useful three dimensional objects to order, is also able to create most of the parts necessary to build another rapid prototyping machine. So for a very low cost, someone with a RepRap should be able to clone a new machine to give to someone else.

It uses the Fused Deposition Modelling  (FDM) system of additive construction where a thermoplastic material is extruded very thinly from a computer controlled nozzle to slowly build up a three dimensional shape layer by layer. (FDM) system of additive construction where a thermoplastic material is extruded very thinly from a computer controlled nozzle to slowly build up a three dimensional shape layer by layer.

However there are various of its own component parts that it cannot currently reproduce such as the stepper motor, microcontroller, extrusion nozzle and lubricant. However over time as the design evolves and becomes more sophisticated it is envisioned that there will be fewer and fewer parts that cannot be made by the machine itself.

Materials

The RepRap team intend to include nozzles for applying different materials during the build process:

- A thermoplastic - generally used to create structure of the object being made.

- Wood's

or Field's metal or Field's metal  which are low melting point metal alloys used to create electrical circuits within three dimensions in the artefact being built which are low melting point metal alloys used to create electrical circuits within three dimensions in the artefact being built

- Ceramic slurry for hard and strong cement-like structures

- Silicone polymer used for gaskets, seals and flexible parts

- Plaster/cellulose mixes, PVA or icing sugar for temporary support material to allow overhangs to exist as the object is being built up. After the object is created these supports can be dissolved away using warm water

Open design

This is an open collaborative design project in that everything relating to it – the schematics, 3D CAD models of the components and the software to run it – are being released under the GPL license  which enables anyone to use, customize and evolve it. The terms of the GPL also mean that any improvements will likewise be available under the same license for others to benefit from. which enables anyone to use, customize and evolve it. The terms of the GPL also mean that any improvements will likewise be available under the same license for others to benefit from.

External links

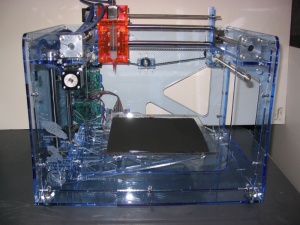

Some RepRap variants:

Fab@Home is an open-source rapid prototyping machine with a syringe-based extrusion system from Cornell University.

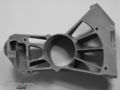

Solid metal objects

As well as CNC machines  which employs subtractive fabrication there are various additive fabrication techniques emerging to create fully dense and strong metal parts straight from a CAD model. which employs subtractive fabrication there are various additive fabrication techniques emerging to create fully dense and strong metal parts straight from a CAD model.

One is selective laser sintering  which more commonly uses nylon powder as its feedstock, but companies such as EOS now produce metal sintering machines which can produce high definition metal parts (or moould tools) directly. Another system, which is coarser but faster than M-SLS is electron-beam melting which more commonly uses nylon powder as its feedstock, but companies such as EOS now produce metal sintering machines which can produce high definition metal parts (or moould tools) directly. Another system, which is coarser but faster than M-SLS is electron-beam melting  , both of which fuse metal powder layer by layer to create a solid metal object. , both of which fuse metal powder layer by layer to create a solid metal object.

Info on ARCAM electron-beam melting:

- Parts are solid and void-free unlike some sintering techniques.

- Layer thickness 0.05mm

- Titanium powder stock. Parts are incredibly strong - even flight certifiable.

- 3 - 5 times faster than SLS

- Done in high vacuum to avoid imperfections caused by oxidation.

Example parts created from titanium powder using ARCAM electron-beam melting:

Engine part

(partly polished)

Images from http://www.arcam.se

3D printed (DMLS) rocket motor

Stainless steel rocket motor chamber Paul Breed from Unreasonable Rocket is attempting to create a Direct Metal Laser Sintered (DMLS) rocket motor with the aim of powering a real hydrogen peroxide fuelled rocket with it. See here and half-way down the page here for more images. Paul has form having previously flown a serious piece of hardware called 'Blue Ball' (a VTOL rocket-powered lander) in the Northrup Grumman Lunar Lander Challenge. Although they failed the competition rules, I would argue it was a pretty successful flight - judge for yourself  here. here.

The Future

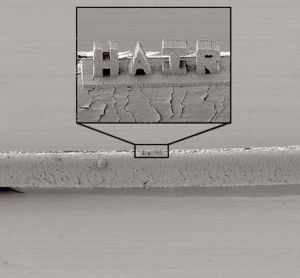

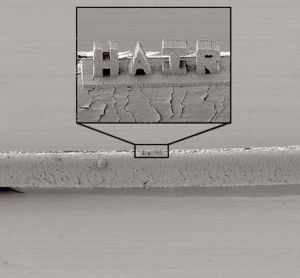

two-photon polymerization/lithography employed to construct the word hair in 3D built upon a human hair - Higher and higher resolution parts (two-photon polymerization/lithography) [1] [2]

[3] [3]

- Multi-material (already here on some models)

- Integrating circuitry into the build

- Integrating off-the-shelf components into the build

- Integrating subtracting and additive manufacturing processes into the same device. Multi-axis milling capability during an additive build giving very smooth surfaces inside and out during the build process

- Human organs (already being done for simple organs like bladders) [4]

TED talk on printing organs TED talk on printing organs

Handling parts

Current prototyping machines typically manufacture one part with one process, and then require a human to pull that part out, do any final finishing, and any further assembly.

Some flexible manufacturing system  have a series of machines, each one optimized for a different process, often with a conveyor carrying parts from one machine to the next.

"CubeSpawn" is an Open Source Free flexible manufacturing system.

A few assembly lines use robotic automated assembly have a series of machines, each one optimized for a different process, often with a conveyor carrying parts from one machine to the next.

"CubeSpawn" is an Open Source Free flexible manufacturing system.

A few assembly lines use robotic automated assembly  . .

Sometimes the parts themselves are designed in a modular way (modular design  ) so they can be easily assembled and disassembled and re-used to assemble something else.

Some open-source modular parts include

MakerBeam Mini-T-slot (is this the same as MicroRAX ?) and the Grid Beam [5][6] system. ) so they can be easily assembled and disassembled and re-used to assemble something else.

Some open-source modular parts include

MakerBeam Mini-T-slot (is this the same as MicroRAX ?) and the Grid Beam [5][6] system.

Keywords

Additive fabrication, 3D printing

|