Difference between revisions of "Additive manufacturing"

| (86 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | {{pagebg}} | |

| + | {{early stage}} | ||

| + | {{turning into real objects navbar}} | ||

| − | + | [[Image:Eden330.jpg|180px|right]] | |

| + | '''Rapid prototyping''' and '''additive manufacturing machines''' are like three dimensional printers that can turn virtual designs on a computer into solid objects, by building up extremely thin cross-sectional layers, using polymers and more recently metals, built one at a time on top of each other. This is known generically as additive fabrication or additive manufacturing in contrast to CNC milling which is a subtractive process, starting from a larger solid block of material. | ||

| − | + | Currently they are used mostly in industry to create accurate parts for developmental designs and prototypes. But they are increasingly being used in short manufacturing runs and is known in this circumstance as ''rapid manufacturing''. | |

| − | + | There are a variety of types currently in use: | |

| − | + | * Fused deposition modelling (FDM) which extrudes thin strands of molten material such as ABS | |

| + | * Selective laser sintering (SLS) which fuses nylon powder or metals with a laser | ||

| + | * Electron-beam melting (EBM) which fuses metal powder using an electron beam in a vacuum | ||

| + | * Stereolithography apparatus (SLA) which cures liquid resin in a tank with an ultra-violet laser. Parts are brittle but can be fully transparent and has a very high resolution | ||

| + | * 3D printing which squirts out a UV curable resin from a matrix of nozzles. Recent machines can have variable colours and variable shore hardnesses, able to create a part that is has gradient of hardness along its length | ||

| + | * Powder and glue plus inkjet colour printing on the surface | ||

| + | * Paper cutting and lamination | ||

| − | > | + | <unfinished> |

| − | + | #Intro | |

| + | #Different types | ||

| + | #Materials | ||

| + | #Advantages | ||

| + | #Current limitations | ||

| + | #Rapid manufacturing | ||

| + | #Inevitability of 3D printers on home desktops (whether commercial or open-source) | ||

| − | >'' | + | There will likely be a convergence of multi-tool rapid-prototyping machines and the shrinking of multi-machine fablabs, allowing sopisticated digital manufacturing from a single desktop device. |

| + | |||

| + | ==[[RepRap]]== | ||

| + | {{:RepRap}} | ||

| + | {{clean break}} | ||

| + | |||

| + | === Some RepRap variants: === | ||

| + | |||

| + | {| border="1" cellpadding="5" cellspacing="0" | ||

| + | |<big><b>Makerbot</b></big> | ||

| + | |<big><b>Ultimaker</b></big> | ||

| + | |<big><b>Printrbot</b></big> | ||

| + | |<big><b>3D Touch</b></big> | ||

| + | |- | ||

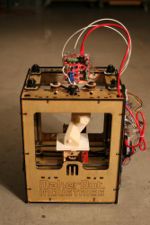

| + | |valign=top|[[Image:Cupcake-cnc-final.jpg|150px|thumb|left|Makerbot's Cupcake]] | ||

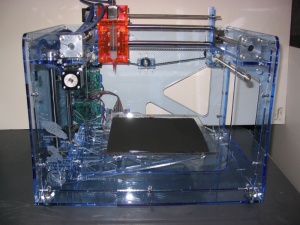

| + | |valign=top|[[Image:Ultimaker2.jpg|200px|thumb|left|Ultimaker]] | ||

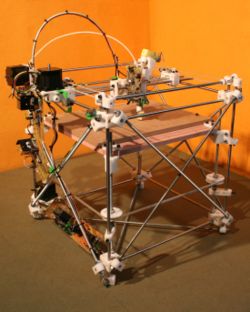

| + | |valign=top|[[Image:Printrbot.jpg|200px|thumb|left|Printrbot]] | ||

| + | |valign=top|[[Image:3DTouch.jpg|200px|thumb|left|3D Touch]] | ||

| + | |- | ||

| + | |valign=top|Makerbot's Cupcake CNC machine is an open-source 3D printer inpired by and partly based on RepRap. Kits are available to buy between $750 and $950 depending on how much assembly you want to do yourself [http://www.makerbot.com Makerbot website]. [http://www.thingiverse.com Thingyverse] - an online repository of 3D objects you can print, started by the guys at Makerbot | ||

| + | |valign=top|http://blog.ultimaker.com | ||

| + | |valign=top|http://printrbot.com [http://www.kickstarter.com/projects/printrbot/printrbot-your-first-3d-printer?ref=card Kicker starter page for Printrbot] | ||

| + | |valign=top|http://www.bitsfrombytes.com/content/3dprinters | ||

| + | |} | ||

| + | |||

| + | == [[Fab@Home]] == | ||

| + | {{:Fab@Home}} | ||

| + | {{clean break}} | ||

| + | |||

| + | == Solid metal objects == | ||

| + | |||

| + | As well as {{wp|CNC|CNC machines}} which employs ''subtractive fabrication'' there are various ''additive fabrication'' techniques emerging to create fully dense and strong metal parts straight from a CAD model. | ||

| + | |||

| + | One is {{wp|Selective_laser_sintering|selective laser sintering}} which more commonly uses nylon powder as its feedstock, but companies such as EOS now produce metal sintering machines which can produce high definition metal parts (or moould tools) directly. Another system, which is coarser but faster than M-SLS is {{wp|Electron_beam_melting|electron-beam melting}}, both of which fuse metal powder layer by layer to create a solid metal object. | ||

| + | |||

| + | Info on ARCAM electron-beam melting: | ||

| + | |||

| + | *Parts are solid and void-free unlike some sintering techniques. | ||

| + | *Layer thickness 0.05mm | ||

| + | *Titanium powder stock. Parts are incredibly strong - even flight certifiable. | ||

| + | *3 - 5 times faster than SLS | ||

| + | *Done in high vacuum to avoid imperfections caused by oxidation. | ||

| + | |||

| + | |||

| + | *Website: http://www.arcam.com | ||

| + | *Article link: http://www.gizmag.co.uk/go/5312 | ||

| + | |||

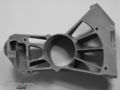

| + | Example parts created from titanium powder using ARCAM electron-beam melting: | ||

| + | |||

| + | <gallery> | ||

| + | Image:Upright m.jpg|Upright | ||

| + | Image:Engine part m.jpg|Engine part<br>(partly polished) | ||

| + | Image:Ice-Axe-Blade.jpg|Ice-axe blade | ||

| + | Image:Gearbox.jpg|Gearbox | ||

| + | </gallery> | ||

| + | <small>Images from http://www.arcam.se</small> | ||

| + | |||

| + | === 3D printed (DMLS) rocket motor === | ||

| + | |||

| + | [[Image:Unreasonable rocket.JPG|300px|thumb|Stainless steel rocket motor chamber]] | ||

| + | Paul Breed from [http://unreasonablerocket.blogspot.com Unreasonable Rocket] is attempting to create a Direct Metal Laser Sintered (DMLS) rocket motor with the aim of powering a real hydrogen peroxide fuelled rocket with it. See [http://unreasonablerocket.blogspot.com/2010/07/more-printed-motor-progress.html here] and half-way down the page [http://unreasonablerocket.blogspot.com/2010_09_01_archive.html here] for more images. Paul has form having previously flown a serious piece of hardware called 'Blue Ball' (a VTOL rocket-powered lander) in the Northrup Grumman Lunar Lander Challenge. Although they failed the competition rules, I would argue it was a pretty successful flight - judge for yourself {{video icon}} [http://www.youtube.com/watch?v=JXwsRJzI8vE&NR=1 here]. | ||

| + | {{clean break}} | ||

| + | |||

| + | == The Future == | ||

| + | |||

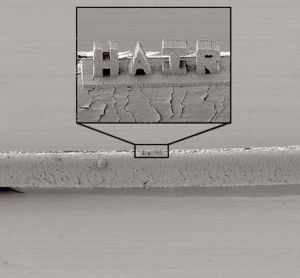

| + | [[Image:Hair.jpg|thumb|300px|two-photon polymerization/lithography employed to construct the word hair in 3D built upon a human hair]] | ||

| + | * Higher and higher resolution parts (two-photon polymerization/lithography) [http://www2.chem.umd.edu/groups/fourkas/research.html] [http://www.tuwien.ac.at/en/news/news_detail/article/7444] {{film icon}} [http://www.youtube.com/watch?v=5y0j191H0kY] | ||

| + | * Multi-material (already here on some models) | ||

| + | * Integrating circuitry into the build | ||

| + | * Integrating off-the-shelf components into the build | ||

| + | * Integrating subtracting and additive manufacturing processes into the same device. Multi-axis milling capability during an additive build giving very smooth surfaces inside and out during the build process | ||

| + | * Human organs (already being done for simple organs like bladders) [http://www.economist.com/node/15543683] {{film icon}} [http://blog.ted.com/2011/03/07/printing-a-human-kidney-anthony-atala-on-ted-com TED talk on printing organs] | ||

| + | [[Image:Printed bladder.jpg|Printed human bladder|thumb|left|300px]] | ||

| + | {{clean break}} | ||

| + | |||

| + | === Handling parts === | ||

| + | |||

| + | Current prototyping machines typically manufacture one part with one process, and then require a human to pull that part out, do any final finishing, and any further assembly. | ||

| + | Some {{wp|flexible_manufacturing_system|flexible manufacturing system}} have a series of machines, each one optimized for a different process, often with a conveyor carrying parts from one machine to the next. | ||

| + | [http://www.cubespawn.com/ "CubeSpawn"] is an Open Source Free flexible manufacturing system. | ||

| + | A few assembly lines use robotic {{wp|Design_for_Assembly | automated assembly}}. | ||

| + | |||

| + | Sometimes the parts themselves are designed in a modular way ({{wp|modular_design|modular design}}) so they can be easily assembled and disassembled and re-used to assemble something else. | ||

| + | Some open-source modular parts include | ||

| + | [http://www.kickstarter.com/projects/701662757/makerbeam-an-open-source-building-kit MakerBeam] Mini-T-slot ''(is this the same as [http://www.microrax.com/ MicroRAX ] ?)'' and the Grid Beam [http://www.kk.org/cooltools/archives/003822.php][http://www.gridbeamers.com/] system. | ||

| + | |||

| + | == Keywords == | ||

| + | |||

| + | Additive fabrication, 3D printing | ||

| + | |||

| + | {{pagebgend}} | ||

Latest revision as of 18:02, 8 July 2012

|