Construction

|

Building a house can be a lengthy, frustrating, expensive project. It takes around 1000 man-hours of labour to build even a small house, projects nearly never finish on time, and construction uses up massive amounts of energy, water and other resources. Building is also very dangerous, with 500,000 deaths and serious injuries annually as a result of construction accidents in the US alone [1].

The difficulty of building is a major reason that a billion of our fellow humans must live in slums and shanty towns[2], where they have only the flimsiest shelter from the elements, face catastrophic damage if hit by a hurricane, earthquake or other natural disaster and have no sanitary way to deal with sewage and waste, allowing infectious diseases to run rampant. Those of us lucky enough to have houses find they require constant maintenance, are prone to leaking, damp and rot, and need constant inputs of water, food and energy, burdening the owners with housework and with bills. Thankfully, there is no reason to continue in this way. It is now the 21st century and we can safely abandon 19th century building methods for something better. Using currently existing technology, it is possible to build – in just a day or two and with relatively little energy – a house that will stand for centuries without needing repairs, keep itself at a comfortable temperature without an input of energy, and produce its own water, energy and sometimes even its own food with little or no ongoing work. We can re-imagine houses as being more than boxes that we sit in. Rather, a house can be an integrated part of an ecosystem, a life-support system that lives in symbiosis with the human animal by providing him with shelter, water, food, electricity and communication. These sustainable, integrated dwellings will be different depending on local climate, population density and personal taste, but willl have in common a high level of autonomy and effective use of resources. Rapid construction methodsHomes can now be produced using digital fabrication techniques. Rather than having carpenters, bricklayers and craftsmen design and make parts on-site (as currently happens), everything can be digitally designed beforehand, allowing for much quicker construction. Open-source modular buildingGridBeam is a modular building system, very much like Lego. It is a collection of pieces that slot and clip together and can be used to build all kinds of structures. The pieces can be fabricated by digital methods like CNC milling or 3-D printed moulds. The designs are all open source. Hexayurt is an open-source hardware program to provide "incredibly cheap shelter for those in need". The initial design was for a simple temporary shelter, but it is evolving over time (as open-source projects always do) into more sophisticated structures.  Buckmister Fuller's Dymaxion house  is a highly-efficient prefabricated house that can be mass-produced on a factory line. is a highly-efficient prefabricated house that can be mass-produced on a factory line.Modular systems like GridBeam, Hexayurt, or the MicroDwellings designed by n55 allow houses to be built by anyone, anywhere, in any size or shape. The amount of labour is reduced from a thousand skilled man-hours to about fifty semi-skilled man-hours. In the very near future, robots could reduce this to zero, making house-building fully automatic. Fitting together modular parts is the sort of task robots are fully capable of. The parts themselves can be fabricated from open-source designs using digital fabrication. Some Fab Labs have already digitally manufactured components and built modular houses. When finished, these look the same as any other house. 3-D printingEntire houses can be made using the same 3-D printing techniques that are transforming industrial manufacturing. Contour Crafting is a technique that has been developed by Behrokh Khoshnevis of the University of Southern California and is currently in the prototype phase. It builds in horizontal layers by squeezing out quick-drying cement from a nozzle. By the time first layer has been finished, the first part of it will have solidified enough to support the second layer. This is much like the 'fused deposition modelling' 3D printing method but on a huge scale. 3D printing method but on a huge scale.

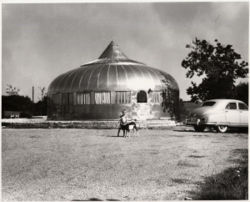

Houses can be designed completely on computer, then the automated construction machine gets to work with no human labour involved. This allows the manufacturing process of Contour Crafting to synergize well with the design process of open collaborative architecture; designs can be shared, downloaded, remixed and printed freely. Houses can be printed with the electrical and plumbing systems incorporated[3]. Where it takes months to build a house using conventional methods, contour crafting will build a house in about twenty hours[4]. This not only makes construction more efficient, it opens up new vistas of design. Walls constructed using this method do not have to be straight (on either the horizontal or vertical axes) so complex organic curved and domed buildings can be made, perhaps mimicking biological structures. Digital manufacturing can make objects of any complexity with equal ease. This fact has enabled geometric designs in jewellery and sculpture that were never possible before; the same will soon happen to the field of architecture. Contour Crafting currently uses concrete, but future developments may use on-site earthen materials. By eliminating the need to bring materials in from elsewhere, we save huge amounts of energy in construction. Construction from on-site materials also has applications in building space habitats[5]. It seems that this type of construction has the potential to be far faster, safer, cheaper and more flexible than conventional construction techniques. Also no house need ever look the same again... See also Loughborough University's research into what they call Freeform Construction and Neri Oxman's work at MIT Softkill Design have announced that they will build a prototype 3D printed house in 2013. 31 pieces of laser-sintered bioplastic are made on the largest 3D printer on the market, then assembled on-site[6]. Pneumatic liftingPneumatic lifting systems use balloons instead of cranes or other heavy machinery to lift objects into place. Amazingly, it is possible to lift 300 tons of wet cement using pressure comparable to puffing on a cigarette [7]. See air-formed domes below. Open collaborative architectureWhen hardware for rapid construction is combined with free designs, it becomes possible for any human being who needs shelter to download and quickly fabricate a home. The Open Architecture Network is a collective that is compiling these free and open designs. This is an example of 'open source' applied to the physical world. We are rapidly moving towards a world where anyone who wants to build a house can download designs from a free and open database. Software can even adapt designs to local factors, so that, for example, the pitch of the roof is increased in areas with heavy snowfall, or the walls are made thicker in areas with cold nights, or a design can be scaled to accommodate different numbers of residents[8]. Architect's fees are typically 5-12% of the cost of building a house(p.12)(p.2). Open, collaborative and computer-aided architecture could reduce this to zero, bringing the cost of construction within the reach of millions more people. Wikihouse is one of several groups working on free and open designs for houses. Their design aims to be functional, digitally fabricable, and radically cheaper than conventional housing. Types of livingryModular housingModular houses, discussed in the construction section above, can be made in any shape or size and to suit any climatic conditions.Molded homes like the retro-futuristic Futuro Geodesic domesThe dome is an amazing shape: it encloses the greatest possible space for a given amount of material and it is also the strongest possible shape. The triangle is another very special shape; it spreads stress evenly, rather than accumulating it at one point. A geodesic dome A geodesic dome can be assembled in less than a hundred man-hours from parts that are mass-produced or digitally manufactured. Air-formed domesDante Bini is an Italian architect who developed an air-formed dome which can be built by laying a flat balloon on the ground, covering it with wet cement, and inflating the balloon. There are over 1600 such domes in the world.Using this method, it is possible to build a house with 20% of the material, 20% of the energy and half the cost of a traditionally-built building of equivalent size [9][10]. (These numbers are for a concrete dome; if low-energy materials are used this could be brought down even further.) The construction takes about an hour. Once built, they require significantly less energy to run than a conventionally-built home. They are also phenomenally strong, essentially invulnerable to natural disasters like earthquakes and hurricanes. In Iraq, a dome like this took a direct hit from a 2300kg bomb and, though the interior was destroyed, the structure itself was unharmed. Alternatively, an inflated balloon can be sprayed with concrete; this is known as a monolithic dome The structure can be extended beyond the basic dome shape to more complex curvilinear structures where several domes are joined together, like the Xanadu house See also —

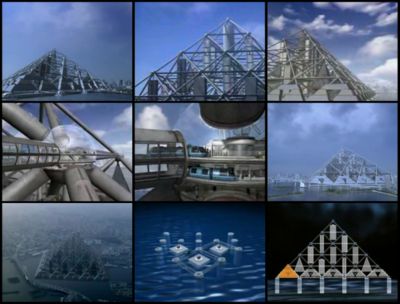

Underground livingryThe single biggest users of energy in the home are heating and cooling devices to mitigate extremes of weather. But a meter or two underground, the temperature never varies; it remains constant at the average temperature of the local climate. By simply digging into the ground, we can tap into a stable temperature and all but eliminate the need for energy to control temperature.Mike Oehler built some astonishingly cheap yet sturdy underground homes, using just wood and plastic sheeting for materials costs of a few hundred dollars or less. These “hobbit-holes” can be excavated by an earth-moving machine and built by semi-skilled labour. A huge advantage is that they require nearly no material to build – just a few wooden support beams – as the walls, floor and roof are simply the surrounding earth. They are completely unaffected by the even the most extreme conditions of wind, heat and cold. Contrary to what Tony Montana said, every day underground is a good day. EarthshipsEarthships are a type of self-sufficient house developed by Mike Reynolds. There are hundreds of them in the world. They are built from old tyres stuffed with earth, and the ground floor is excavated a few feet deep. The living space is therefore surrounded by earth, as with “hobbit-holes”. Earthships can be thought of as a semi-underground home. Because of the huge thermal mass provided by the thick earthen walls and the surrounding earth, they require no energy to heat or cool. A drawback is that Earthships require as much labour to build as a conventional house,Earthships are unique in using rammed-earth tyres to build walls. They also make full use of several techniques common to many sustainable building projects: composting toilets, rainwater catchment, greywater harvesting and small-scale point-of-use energy generation. No pipes or wires go in or out of the house – no gas pipes, no sewage pipes, no water pipes and no power lines. The hundreds of Earthships in daily use around the world are living proof that no matter where you are, you can build a home that is self-sufficient for heat, energy and water. Living at seaWe have enough land to sustain a population of tens of billions of people on Earth (not to mention space colonies), but apart from our land-space there is an even more abundant area that we rarely realize is available for habitation: the world's oceans.The Seasteading Institute has championed the idea of “homesteading the high seas”. But the technology of getting large structures to float and be stable on the sea has been well-established for many decades in semi-submersible oil rigs Living at sea comes with certain advantages. The first and most obvious is the ability to inhabit vast areas that would normally be considered uninhabitable. Growing food at sea is not only possible, it is more productive than growing on land. Sources of energy at sea are also abundant. FLOATEC is a company designing simple technologies for building floating houses with recycled polystyrene foundations. Arcologies The Shimizu Mega-Pyramid  was a proposal for a massive arcology in Tokyo Bay. It would have been by far the largest building in the world, with a footprint of 8km2, and would have been home to 750,000 people. The project eventually faltered because of financing issues rather than technological ones. was a proposal for a massive arcology in Tokyo Bay. It would have been by far the largest building in the world, with a footprint of 8km2, and would have been home to 750,000 people. The project eventually faltered because of financing issues rather than technological ones.One is energy-efficiency. The two biggest draws of energy are transport and heating/cooling indoor spaces. As population density rises, the energy needed for transport drops [11]. Also, densely-packed apartments require much less energy for heating than detached houses because they have less exposed surface area. Arcologies, being the most compact form of living ever devised, would be the most energy-efficient. A related advantage is easy, efficient transport. People living in an arcology would have nearly everything they need within their own building, so long commutes along roads would be unnecessary. Transport would be convenient, efficient and congestion-free. Most designs, such as the Shimizu Mega-Pyramid, use some sort of personal rapid transit.  Vincent Callebaut's beautiful 'Lillypad' design for a floating arcology. This marries the idea of an arcology to that of seasteading. Each Lillypad would allow 50,000 people to live at sea. Swarms of them could form megacities entirely at sea, capable of sustaining themselves without undesirable environmental impact. We normally think that mankind has fixed, limited living space on the land's surface; but an innovation like these floating arcologies allows us to transcend this limit. Building materialsCurrently, 40% of all material use by mankind is for construction[12][13]. This comes with enormous waste, environmental damage and unnecessary expense. Adobe Straw bale insulation is cheap and can be produced with a tiny amount of energy. Building with self-healing materials is being researched. Living buildingsAutonomyWaterAs water is vital to human life, any human habitation worthy of the name should be equipped with the means to harvest rainwater and filter it with simple, point-of-use filters. If employed in tandem with greywater harvesting and composting toilets, this can make any house can become self-sufficient for water. Places with neither rain nor subterranean water can use atmospheric water generators. Rainwater harvestingAs discussed here, just about any house can be fitted with a cistern to catch rainwater and this will provide for all the water needs of the inhabitants. GreywaterVery clean water is needed for drinking, cooking and showering. For other purposes, such as flushing toilets or watering gardens, the runoff water from a shower or sink can be used. This is known as greywater harvesting ToiletsConventional toilets use about 5 liters of water every time they are flushed. This accounts for about a quarter of domestic water use. Composting toilets, on the other hand, use no water whatsoever and also produce compost for growing plants. If properly designed, they are hygienic and smell earthy, not foul. Toilets can also be flushed with seawater, a very abundant, low-value resource. This technology has been in widespread use in Hong Kong for decades. FoodUrban people can grow their own food in just a few square meters using aeroponics, while rural people could feed a family of four in a permaculture garden surrounding their house to a radius of 15m or less. EnergyIt is entirely feasible for just about any building to generate all the energy it needs on-site. The source of energy will vary depending on the environment, and the available technology. Some places may have a small wind turbine on the roof, or flying above the house on a cable. Other places may be able to fulfill their energy needs by putting solar panels on the roof. In the near future, solar panels will be embedded in widows and painted onto walls as well. In places by the sea or by a river, energy from the water can be used. In places without wind, sunshine or moving water, geothermal systems and microbial fuel cells can still provide ample energy. Heating and coolingThe biggest demand for domestic energy use is usually heating and cooling. (For instance, 82% of domestic energy use in the UK is for heating[15].) The proper architectural design can allow a building to remain at a comfortable temperature year-round without any need for energy to be used. This is called a passive house

HygieneAs noted above, one of the major threats that comes with inadequate housing is the threat of infectious diseases. Buckminster Fuller's dymaxion bathroom Bathrooms can be equipped with ultraviolet LEDs that are programmed to switch on when the room is empty, sterilizing the room completely in 10-30 minutes. (Though care must be taken not to use UV-sensitive plastics in the bathroom fittings.) Substances have been developed that, when sprayed on to a plastic surface, bind to it permanently. Once the plastic has been treated in this way, it kills nearly all bacteria on contact[16]. |

[print version]

[print version]  [update]

[update]  [site map]

[site map]