Automated transport systems

Main Page > Advanced automation > Automated infrastructure > Automated transport systems

Main Page > Advanced automation > Automated infrastructure > Automated transport systems

|

If infrastructure is to be automated, there obviously needs to be automated transportation. Taking raw materials to processing plants, processed materials (such as machine parts) to manufacturing plants, and products to their destinations - all this haulage is laborious and unstimulating work. It is desirable to free people from such tasks using technology. For an automated post-scarcity infrastructure to be a reality, there must be not only vehicles capable of moving around autonomously, but also automated logistical systems that are capable of directing these vehicles. Autonomous logistics is now a fully mature technology; there are computers that can autonomously manage warehouses, order products that are running low, and ship packages around the world. Connect these smart logistical systems to driverless vehicles and you have an automated transport infrastructure, capable of joining together a post-scarcity world economy. Bear in mind that decentralizing the means of producing food, water, energy and machinery will massively reduce the amount of haulage to be done. When you can fabricate everything you need and most of the things you want in your backyard, there is no need for anything to be delivered to you except for raw materials like scrap metal. It has been said that with digital fabrication, products travel most of their journey at light-speed in the form of information. As well as cargo, our own means of travel can be greatly improved using existing technology. Luckily, better methods of transport exist. A few of the more exotic ones are explored below, but a more familiar example is the train. Trains are one of the most efficient forms of transport in terms of energy per unit weight moved. They are also the easiest to automate, with some already being so, such as the Docklands Light Railway

Imagine you need to get across town for a party. You leave your house and walk along a tree-lined pedestrian avenue. Overhead is a light, silent monorail with pods zipping along it. After a hundred metres, you come to a stairway along the track, climb it and press a call-button, just as you would for an elevator. Within two minutes, a pod the size of an automobile, made of lightweight, strong materials, glides up to you, stops, and opens its doors. You get in and find a console with a touch-screen map of the city. You select your destination, sit back and enjoy the ride as the pod whizzes to the party at 100 miles per hour without ever stopping. This is Personal Rapid Transit (PRT). It combines the personal size and customized routing of a car with the speed, efficiency and automation of light rail. A central computer plots the quickest route for the pod to travel from any point in the system to any other point, co-ordinating the movement of every pod in the system so that each can travel without having to stop. A city built using PRT in lieu of roads (such as Masdar City in the United Arab Emirates) would allow for quick, clean, automated, energy-efficient, point-to-point transport 24 hours a day, seven days a week. Since PRT would take up a lot less space than roads, we could reclaim the huge amount of urban land that is devoted to transport in 20th century-style cities and devote it to something more pleasing.PRT has been technically and logistically feasible for decades, but economic and political difficulties have held back its development. PRT is a logistical concept more than a technological one. It could be implemented with a variety of technologies: rail-based or wheel-based vehicles, on-board or in-track propulsion and using a variety of energy sources. It can run at ground level, underground or on elevated tracks. Magnetically-levitated pods would allow for especially high speed and energy-efficiency. Morgantown, West Virginia's PRT system has been successfully in operation since 1975. It now carries 16,000 passengers a day, costs only 50 cents and has a reliability rate of 98%. Personal Rapid Transit is the most efficient way to move people around a city, while VacMagLev is the most efficient way to move people and goods long distances. However, these systems require large infrastructures and — for now — are probably feasible only in planned towns and new developments. Existing infrastructure is dominated by roads. For example, in the European Union, 44% of goods and 85% of people are transported by road [2]. Shifting some of this onto rail will increase efficiency, but we can also get much better use out of our road system. We have the technology to make self-driving, electric cars that use a fifth the energy of conventional cars and are much safer. Current situationCurrently, cars are very wasteful of energy, are responsible for 28% of greenhouse gas emissions [3] and waste a lot of valuable urban space. They are also extremely dangerous. Due to its everyday nature, we sweep under the carpet how risky driving really is. The annual global death toll in road accidents is an amazing 1.2 million people per year and 15 million people are seriously injured[4][5]. This is the equivalent of Auckland, the biggest city in New Zealand, being nuked each year, and every man, woman and child in New York and Hong Kong being severely injured every single year. Unbelievably, of everyone who died worldwide in 2002, 2% - one in fifty - were killed by road traffic accidents [6][7]. Road traffic accidents are the number one killer of young people [8] and by far the leading cause of accidental death [9]. This is clearly unacceptable. Then there is the question of traffic congestion. An efficient transport system, by definition, would use space optimally, co-ordinate the movements of different vehicles so they do not block each other, and put each vehicle to full use. Road-based transport is currently far from this ideal; at peak times, only 8% of the space on motorways is actually occupied by a car [10], traffic jams eat up 4.2 billion man-hours a year in the US alone [11] and cars spend 96% of their time parked[12], during which time they do nothing but take up valuable space. EfficiencyConventional cars expend a majority of their energy moving dead weight and pushing air aside, rather than actually transporting the passengers. They are very heavy and are not designed to be aerodynamic.

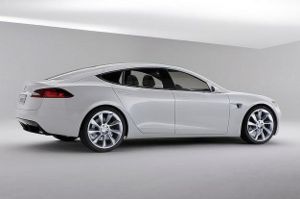

A car's energy efficiency is often expressed in miles-per-gallon (mpg), the number of miles a car can travel using the energy contained in one gallon of petrol. Most cars get under 40mpg, but it is possible to get energy-efficiencies well over 100mpg. The two-seater Volkswagen 1-liter car gets well over 200mpg, and the two-person electric cars the X-tracer, Li-ion Motors' Wave II, the Aptera and Urbee get 205.3mpg, 187mpg, 164.3mpg and 150mpg respectively. Another electric two-seater, Trev, is said to use "less than 1/5 of the energy use of a conventional car"[13]. For larger, four-person cars, efficiency can also also surpass 100mpg. The ethanol-powered Edison2 Very Light Car gets 102.5mpg, while the electric Tesla Model S gets 100mpg and can seat five adults and two children. Conventional cars are much, much heavier than they need to be. A lot of energy is wasted in moving this weight around. By making cars out of composites that are both lighter and stronger than steel (such as carbon fiber), we can save a lot of energy while making cars much safer. The X-tracer weighs just 651kg, Trev weighs 300kg and the Edison2 Very Light Car, as its name hints, weighs just 376kg.  The Urbee gets 150mpg and is the first car to have its body made on a 3D printer  reduces energy needs by 10%. reduces energy needs by 10%.

Electric carsElectric cars have been around for over 100 years, but two things have held back their adoption. Whereas conventional cars can travel about 400 miles before needing to refill the tank, electric cars often had ranges under 100 miles. The second problem was that the batteries took too long to refill. While you can fill a tank of petrol in a few minutes, electric cars often needed to be left to charge overnight.  The Tesla Model S, an electric car that can travel 300 miles on a single charge and recharge in 45 minutes. It achieves this using a lithium-ion battery that weighs 540kg and stores 85kWh of energy [1] — an energy density of 157 watt hours per kilogram. New battery technologies — which have been demonstrated but not yet integrated into production cars — have much higher energy densities (i.e. store more energy per unit of weight), allowing for greater range. Lighter batteries further reduce dead weight and increase efficiency. These new battery technologies also recharge faster:

Designing cars for efficiency, as discussed above, allows you to travel much further with a given amount of energy. An Audi A2 can travel 443.7 miles with a Kolibri Alphapolymer battery, but the same battery in a highly-efficient car like those discussed above would give a range over a thousand miles. Nanowire or lithium-air batteries would allow efficient cars to travel perhaps ten thousand miles per charge, and recharge as quickly as it takes to fill the tank of a petrol-powered car. Hydrogen fuel cell carsStoring a car's energy as hydrogen allows similar range and recharge time to petrol. If an infrastructure can be built that allows people to conveniently fill up on hydrogen, then zero-emission cars will be possible without further improvements in technology. One idea is to turn home garages into hydrogen-refuelling stations [28]. Self-driving carsA lot of progress has been made in developing autonomous cars Open-source carsCars are not exempt from open collaborative design. As of May 2011, p2pfoundation lists 18 open-source projects to design and build a car, of which one has reached production. Most of these are designed to be environmentally benign, such as Trev, the 300kg electric two-seater mentioned above, OScar (which runs on biofuels), and "c,mm,n" and Riversimple's Hyrban, which both run on hydrogen fuel cells. SafetyThese technologies can eliminate most of the alarming amount of destruction that happens on the roads. Computer-controlled cars that can accurately sense their environment, make precise calculations, and do not get tired, distracted or drunk will have far fewer accidents than human drivers. Cars made of stronger materials will stand up to crashes better. (The Aptera, which is made of a lightweight honeycomb composite, will not dent when hit with a hammer.) It was mentioned above that a huge reduction in the weight of cars can be achieved and that this will improve energy-efficiency. Another important reason to reduce weight is to make accidents less serious incidents. Other factors being equal, it is preferable to be hit by a 400kg car than a 1400kg one. Progressive cars can even be designed with bumpers made of something soft like foam or rubber, in order to soften blows to pedestrians and cyclists.

Cargo ships can carry goods from port-to-port, but these leaves the "last mile problem" of getting them from the port to the doorstep. An exciting technology that is currently emerging is autonomous flying quadrotors. These are small, lightweight flying robots that are capable of very agile flight. The technology has progressed in leaps and bounds in recent years, and their extraordinary agility can be seen in this video from MIT.

Such flying robots are often developed for military and surveillance applications, but have great potential when applied to the problem of delivering packages. MatterNet is a startup company working on making this a reality. They are focused especially in regions with inadequate roads. The MatterNet Vision video explains more. A start-up company called TacoCopter have envisioned a more whimsical application of the technology. They want to allow people to order tacos on their smartphone at at any hour of the day or night and have them delivered by autonomous drones. Several open-source hardware flying drones already exist: Aeroquad, MicroKopter and DIY Drones Combined with automated logistics software to control the robots, this could create a delivery service that operates almost invisibly, without noise or congestion, uses a tiny amount of energy (solar-powered charging stations could readily meet the energy needs of the drones) and no labour at all.

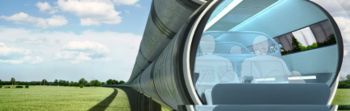

As noted above, trains are one of the most energy-efficient means of moving people and freight from A to B. What energy is lost is mostly due to the friction between the wheels and and the track, and the friction between the train and the air (i.e. air resistance). Magnetic levitation (MagLev) trains solve the first of these; they have no friction between the trains and the tracks because the train does not touch the track. Instead it hovers above it due to electromagnetic repulsion between the two. MagLev trains are therefore much more efficient and capable of greater speeds than ordinary trains. MagLev trains have been in use for decades. The second energy-drain, air resistance, can be eliminated by housing the MagLev train in a vacuum. This is called vacuum-enhanced magnetic levitation (or VacMagLev, or VacTrain technology, or evacuated tube transport) and was pioneered by Gerard O'Neill, who said that VacMagLev would allow goods to travel "from New York to Orlando in half an hour... [using] less energy than... a liter of gasoline"[30]. Of all the new transport-technology options on the menu for 21st century man, VacMagLev is outstanding for its speed, its energy-efficiency and the ease of automation. One proposal by Daniel Wade outlines how such technology could be used to move goods of any kind around the world at an incredible 3200km/h (2000mph) with minimal energy. The most ambitious designs envision speeds of up to 8000km/h (5000mph). To put this in perspective, this is about ten times the cruising speed of a commercial jet aeroplane and would mean travelling from New York to Los Angeles in about 35 minutes. A network of such pipes could be set up between the world's cities, allowing goods to be moved from anywhere to anywhere in a few hours. Some proposals see this as a means of transporting people, a much faster and more efficient alternative to flying. Other designs have narrower tubes used for moving goods around. To build such a system would require considerable initial investment. One optimistic estimate puts the cost of building a vacuum-enhanced maglev system at $2 million per mile of track ($1.25m / km) [31] for a tube big enough to carry people. It is possible that automated construction methods would allow track to be extruded cheaply by machines. The running costs, however, would be much lower than air travel and this would justify the initial effort of construction. This is true even if we consider only the financial savings, not to mention the reduced environmental impact and the energy and time saved. It takes at least 3 liters of kerosene to move each passenger one kilometer by plane (p. 12)[32], so fuel costs are over $2.50 per passenger per kilometer[33]. By contrast, the energy requirements of VacMagLev are tiny and could easily be met by solar panels on the tubes, allowing the system to run at zero fuel cost. If 500,000 passengers are transported, the fuel savings equal the cost of construction ($1.25m / km). For the world's 50 busiest air routes In July 2013, the VacMagLev concept was reawakend by Elon Musk with a design he calls the Hyperloop Imagine a city with clean air free of the noise of engines, where you can get from anywhere to anywhere at 50mph (80km/h) or more without any danger of death, where the problems of traffic and parking are fully solved. This is entirely feasible with technology that has been around for many years; all we must do is eliminate the gross inefficiencies inherent in using private cars for urban commutes. Small, light vehiclesIf you look at the cars choking up city streets at rush hour, you will notice that over 75% of them are carrying only one passenger. Yet that one passenger is using a vehicle that weighs more than a ton and is over 3m long and 1.5m wide. To travel, you really only need something the size and weight of a bicycle and to travel in luxury you need something about the size of an armchair. If we reduce the amount of road-space per traveller from a car-footprint to an armchair-footprint, we increase the capacity of the roads four or five times. This in itself would almost entirely eliminate traffic congestion. If these small vehicles are driven by sophisticated AI capable of driving close together at speed, safely weaving in and out of other moving vehicles, then congestion will certainly be a thing of the past. This would allow vehicles to move around cities at, say, 50mph (80km/h). By comparison, the average speed around London is just 12mph (19km/h) [34] Cars are designed to be able to travel hundreds of miles carrying five people and a full boot. Using such a vehicle to travel 5 miles carrying one person and a briefcase is like hiring the Trojan army to solve your 6-year-old son's bullying problem; it is excessive. Yet this is exactly how we use our cars the majority of the time: 77% of Americans drive cars to work with no passengers[35], 55% of car journeys in the UK are under 5 miles[36] and 49% of those in the US are under three miles[37]. Using cars for these journeys represents a huge waste of energy and space and causes the aggravation of parking and traffic - which are a huge waste of time. We can reclaim this if we make these short urban commutes in vehicles like:

Velomobiles are recumbent bicycles or tricycles enclosed in an aerodynamic shell. They are faster, more stable and more comfortable than bicycles, require less effort, and keep rain off the passenger - solving all the main drawbacks of cycling. The main obstacle to adopting velomobiles thus far has been the expense of crafting the shell. However, 3D printing could greatly reduce that. Vehicle sharing schemesCars spend 96% of their time parked. That is to say, they spend 96% of their time wasting space. If we can find a way to reduce this to, say, 50% of the time, we would reclaim huge chunks of our cities now devoted to parking. This can be achieved by sharing vehicles so that when one person parks a vehicle, another person can come along and use it. This can be done either by leaving the vehicle at a shared dock, or, if this is not convenient, having a wireless transmitter that allows people to have the location of the nearest vehicle sent to them by SMS (as the bicycle-sharing scheme in Berlin currently does). The bicycle sharing scheme in Lyon achieves 10-15 uses per bicycle per day[38], while in Paris the bikes are taken out 8-10 times per day[39]. Compared to privately-owned cars, which are used perhaps 3 times a day, this is much less wasteful of space and of vehicles themselves. Because these vehicles are much smaller than cars, the amount of city space needed for parking can be reduced from a car-footprint 96% of the time, to an armchair-footprint 50% of the time — about a nine-fold decrease. Many cities already have bicycle sharing schemes  and there is no reason the same model cannot be extended to other light, urban vehicles. The winner of the 2009 Buckminster Fuller challenge was a proposal for a fleet of shared small electric cars and electric scooters which would be docked at points around a city (where their batteries charge). There are plans to bring this in for several cities[40] and commercialization is planned for late 2012 [41]. and there is no reason the same model cannot be extended to other light, urban vehicles. The winner of the 2009 Buckminster Fuller challenge was a proposal for a fleet of shared small electric cars and electric scooters which would be docked at points around a city (where their batteries charge). There are plans to bring this in for several cities[40] and commercialization is planned for late 2012 [41].

(A rather more futuristic extension of this idea is also possible — rather than going to pick up a parked vehicle, what if you use your phone to get it to come to you? This would be possible with current autonomous vehicle technology. If the technology reaches this level of sophistication, it will be equivalent to a road-based PRT system.) 90% of international trade is moved by ship[42]. Imagine if all this cargo could be moved about for free: without no input of human labour or fuel. It would create a true abundance of transport. An autonomous, clean cargo ship is feasible with currently existing technology. As it would have no fuel or crew costs, even a higher initial construction cost than normal cargo ships would be justified. Ships are comparatively easy to automate, as there are not many things to bump into out at sea, and they do not have to deal with the high-speed manoeuvering that has challenged designers of autonomous helicopters and cars. There are plenty of small unmanned military boats (USVs for 'unmanned surface vehicles' in military-speak) in operation already, though this technology has not been much applied outside of the military nor on larger boats. With GPS, it is very easy for a ship to be programmed to go from anywhere to anywhere else. Loading and unloading cargo ships has become more and more automated since the 1950s and it is now possible to get containers off ships and into trucks without any human labour. There is an abundance of clean energy available at sea. The large surface area of a ship provides ample space for sails and solar panels, and wave power can also be harnessed. There are several ways to make ships more energy-efficient. One is to design large catamarans, which tend to use less fuel than monohulls of equivalent size. Catamarans tend to rock more than monohulls, though this may not be a problem for many cargo ships. Trimarans, if properly designed, can offer both the efficiency of a catamaran and the stability of a monohull [43]. Sail-power is making a comeback in commercial shipping. It makes commercial sense to avail of a free source of energy and sails can now be computer-controlled to automatically turn to the angle that best catches the wind. SkySails are a bit like kitesurfing; a kite-like sail floats above the ship on cables and provides extra pull to move the ship forward. Because the sail is at a higher altitude, it is able to catch the faster winds that exist higher in the air. SkySails provide 10-35% of the energy a ship needs[44] and run completely autonomously, adjusting themselves to the changing winds.Although there are designs for large cargo ships with zero emissions and small autonomous boats with zero emissions[45] [46], there are not yet any designs for large, autonomous, zero-emissions cargo ships. Time for an open-source design project, perhaps? One promising technology for moving freight around the world would be to create lighter-than-air, solar-powered, high-altitude, high-speed airships. At least one design for such a craft has already been worked out. The craft is filled with helium, making it lighter than air and allowing it to rise into the sky without using energy. It is designed to fly at a height of nearly 11000m. At this altitude, air is thinner, so less air-resistance is offered to the unaerodynamic bulbous airship moving through the sky. The large top of the airship is covered with solar panels and because it flies above all cloud-cover and above 11km of air that blocks the sun's energy, it is able to access abundant solar energy, regardless of the weather. It can fly day and night at speeds of about 200km/h. |

[print version]

[print version]  [update]

[update]  [site map]

[site map]