Difference between revisions of "Virtual designs into physical objects/Mail order machining"

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

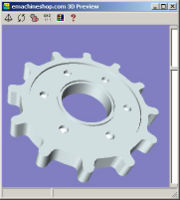

| − | [[Image:EMachineShop.jpg| | + | [[Image:EMachineShop.jpg|180px|right]] A company called [http://www.emachineshop.com eMachineShop] takes custom fabrication a step further in terms of ease of use. The US-based company supplies a fairly simple computer-aided design program that once materials have been assigned to the geometric forms an automatic bill of materials can then be calculated. When the user is happy with the design and the price, the information is sent over the internet to eMachineShop where the parts are fabricated using the appropriate [http://www.emachineshop.com/machines/index.htm computer-controlled machinery]. The finished parts are then mailed back to the user. |

| − | eMachineShop have cleverly incorporated the limitations of their physical fabrication processes into the CAD program. This means that the company can be sure that they can make anything designed using their software. The company | + | eMachineShop have cleverly incorporated the limitations of their physical fabrication processes into the CAD program. This means that the company can be sure that they can make anything designed using their software. The company claims to handle part quantities from one-offs to runs up to a million. |

| − | [[Image:Pcb-design.gif| | + | [[Image:Pcb-design.gif|180px|right]] |

A related company is [http://www.pad2pad.com Pad2Pad] that provides a similar service for the creation of printed circuit boards (PCB). They also provide free design software that has circuit error-checking and costing built-in. When the design is completed it is sent electronically to the company who then fabricate the PCBs and return by post. They do not currently populate the boards with electronic components, although it is likely to be only a matter of time before a full electronics service such as this is offered. There is on-going research to create functional circuitry via cheaper methods, such as inkjet printing [http://www.epson.co.jp/e/newsroom/news_2004_11_01.htm], that will make creating electronic circuits even more accessible. | A related company is [http://www.pad2pad.com Pad2Pad] that provides a similar service for the creation of printed circuit boards (PCB). They also provide free design software that has circuit error-checking and costing built-in. When the design is completed it is sent electronically to the company who then fabricate the PCBs and return by post. They do not currently populate the boards with electronic components, although it is likely to be only a matter of time before a full electronics service such as this is offered. There is on-going research to create functional circuitry via cheaper methods, such as inkjet printing [http://www.epson.co.jp/e/newsroom/news_2004_11_01.htm], that will make creating electronic circuits even more accessible. | ||

| + | |||

| + | See also http://www.batchpcb.com | ||

Latest revision as of 12:49, 18 July 2010

A company called eMachineShop takes custom fabrication a step further in terms of ease of use. The US-based company supplies a fairly simple computer-aided design program that once materials have been assigned to the geometric forms an automatic bill of materials can then be calculated. When the user is happy with the design and the price, the information is sent over the internet to eMachineShop where the parts are fabricated using the appropriate computer-controlled machinery. The finished parts are then mailed back to the user.eMachineShop have cleverly incorporated the limitations of their physical fabrication processes into the CAD program. This means that the company can be sure that they can make anything designed using their software. The company claims to handle part quantities from one-offs to runs up to a million.

A related company is Pad2Pad that provides a similar service for the creation of printed circuit boards (PCB). They also provide free design software that has circuit error-checking and costing built-in. When the design is completed it is sent electronically to the company who then fabricate the PCBs and return by post. They do not currently populate the boards with electronic components, although it is likely to be only a matter of time before a full electronics service such as this is offered. There is on-going research to create functional circuitry via cheaper methods, such as inkjet printing [1], that will make creating electronic circuits even more accessible.

See also http://www.batchpcb.com